Fibre finishing and enhancement

TWE offers a range of finishing and enhancement processes.

Physical enhancement:

a. Calendering

TWE nonwovens can be finished with a special surface to give them properties such as a smooth surface, the textile can be lasered, or calibrated by means of calendering.

b. Lamination

Our nonwovens can be laminated with various different materials, such as woven materials, nonwovens, films or knitted materials to lend the nonwoven new properties.

There are various lamination methods available:

- Needle punching: The laminate is unrolled in front of the needle machine and needle-punched into the nonwoven.

- Hot air: The laminate, which contains adhesive, is guided through a hot air oven which activates the adhesive, and the laminate then bonds with the nonwoven.

- Powder: The laminate is rolled out to the powder spreader and applied to the nonwoven using pressure and heat

- Hotmelt: The laminate is rolled out to the hotmelt spinner and applied to the nonwoven using pressure

Chemical enhancement

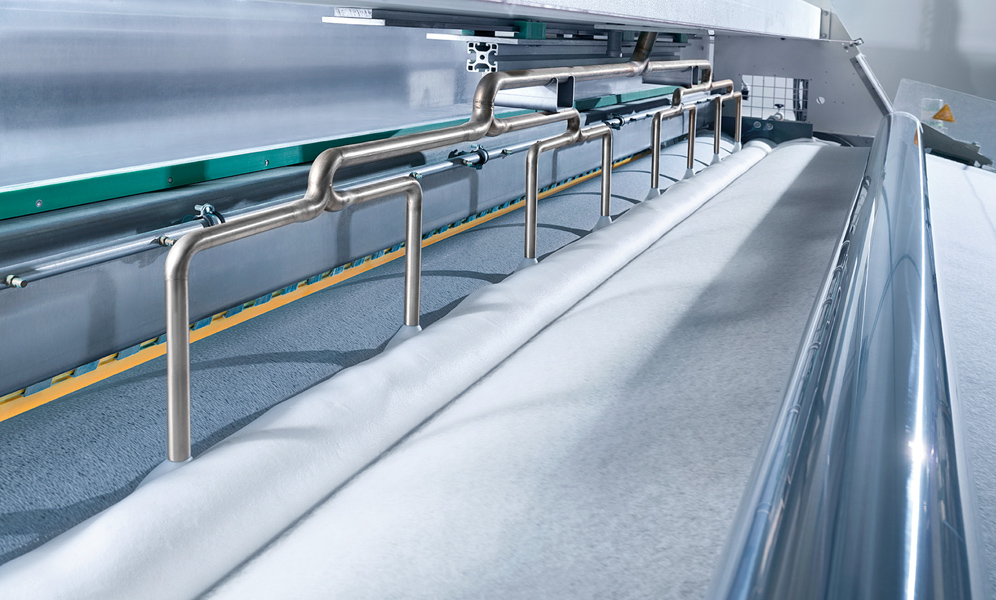

a. Liquid finishing

Aqueous chemicals can enhance our nonwovens in the following processes:

- Spraying: Water-based chemicals are sprayed as an aerosol on the surface of the nonwoven via a nozzle system.

- Immersion: The nonwoven is fully immersed in a bath of chemicals.

- Foam foulard: This method allows chemicals with a higher binder and lower water concentration to be applied to nonwovens.

This broad range of technologies enables TWE to offer finishes with flame-resistant chemicals, fluorchemicals or antimicrobial chemicals.

b. Powder spraying solids: In this method, hoppers and rotating brushes apply adhesive powder to the nonwoven.

Powder spraying enables TWE to offer nonwovens to which thermoplastic or duroplastic resin can be applied.